Deterioration

The evaluation of pavement distresses is carried out accurately and efficiently through the use of advanced technologies, such as the FIONA I and FIONA V systems. These devices are specialized tools designed to measure and analyze the condition of road surfaces in detail.

FIONA I and FIONA V employ state-of-the-art technology, including laser scanning systems and high-resolution cameras, to capture real-time data on road condition. This data includes information on cracks, deformations, irregularities, and other types of deteriorations that may affect pavement integrity.

The use of these systems not only enables early identification of issues but also facilitates the planning of preventive maintenance interventions. With access to precise and up-to-date data, road authorities can make informed decisions to address deterioration in a timely manner, maximizing the effectiveness of resources allocated to road infrastructure maintenance.

Deflection

Road deflection is a fundamental parameter that provides valuable information about the structural capacity of pavements. This indicator measures the flexing or deformation experienced by the pavement surface under applied loads. Essentially, deflection reveals pavement strength and load-bearing capacity, making it crucial for assessing integrity and durability.

To measure deflection accurately, specialized equipment such as the FWD (Falling Weight Deflectometer) and HWD (Heavy Weight Deflectometer) is used. These devices apply controlled loads to the pavement and measure its response, recording the resulting deflection. The collected data is essential for evaluating pavement structural capacity and planning maintenance and rehabilitation actions.

In summary, deflection, measured using equipment such as FWD and HWD, plays a critical role in assesing pavement structural condition, enabling road authorities to make informed decisions that ensure effective maintenance and extend infrastructure service life.

Inventory

Road inventory plays a vital role in the effective management and maintenance of road infrastructure. This process collecting, organizing and analyzing detailed information about a region’s road network. Advanced equipment such as FIONA I and FIONA V is used to perform this task efficiently.

The FIONA I and FIONA V are specialized tools designed for comprehensive road inspection and evaluation. These systems utilize cutting-edge technologies, such as laser scanning and high-resolution cameras, to capture accurate data on infrastructure condition. From crack detection to pavement quality assessment, they provide a complete oview of road conditions.

By conducting road inventories using FIONA I and FIONA V, road authorities can obtain detailed information about road geometry, signage, potholes and other critical elements. This detailed knowledge facilitates planning of maintenance and rehabilitation projects and supports informed decision-making regarding investments and improvements to the road network.

In summary, the use of advanced equipment such as FIONA I and FIONA V not only improves data collection efficiency but also provides a solid foundation for strategic road management, ensuring safe and more durable roads.

Friction Coefficient

This parameter is a fundamental measure of skid resistance between vehicle’s tires and the road surface, directly affecting vehicle control and traction. To accurately evaluate this coefficient, a specialized device known as the Grip Tester is used.

The Grip Tester measures the friction between vehicle tires and the pavement surface. The higher the friction coefficient, the better the road’s ability to provide traction, essential for preventing skidding and ensuring safe driving, especially under adverse weather conditions.

The results allow identification of areas with low friction levels, which may indicate worn pavements or hazardous conditions. This information guides maintenance and improvement decisions, significantly contributing to the safety of drivers and pedestrians.

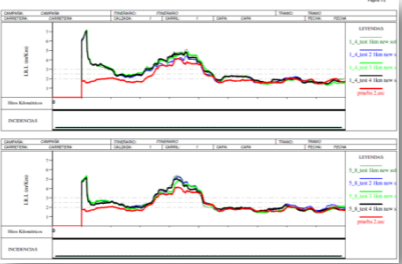

IRI

Road inventory plays an essential role in the effective management and maintenance of road infrastructure. In this process, detailed information about a region’s road network is collected, organized, and analyzed. To carry out this work efficiently, advanced equipment such as FIONA I and FIONA V are used.

The International Roughness Index (IRI) is a key parameter for evaluating pavement quality. This indicator provides information on surface irregularity, directly affecting ride comfort and pavement durability. Accurate IRI measurement is carried out using specialized equipment such as Fiona I, Fiona V, and Profilometer.

Fiona I and Fiona V are advanced tools that employ technologies such as laser scanning and high-resolution cameras to assess pavement texture and roughness. These systems collect detailed data that contribute to precise IRI determination. Additionally, the Profilometer is another valuable tool that measures road elevation along its length, allowing a comprehensive profile assessment and IRI calculation.

The combined use of these devices provides road authorities with a complete view of pavement quality and its impact on driving experience. IRI data obtained through with Fiona I, Fiona V, and a Profilometer is essential for planning maintenance and rehabilitation interventions, ensuring safer and longer-lasting roads.

Horizontal and Vertical Retroreflection

Both vertical and horizontal retroreflectivity plays a crucial role in road safety by improving the visibility of traffic signs and road markings under low-light conditions. The RetroSign GRX-3 retroreflection gun is an essential tool for accurately measuring these properties.

The RetroSign GRX-3 evaluates the effectiveness of vertical and horizontal surfaces by measuring their ability to reflect vehicle headlight beams. By emitting light towards signs and pavement markings and measuring the reflected light, the device determines retroreflective performance. Adequate retroreflection ensures that signs and markings are clearly visible, improving driver guidance at night.

Data collected using the RetroSign GRX-3 pistol is essential for maintaining high road safety standards and ensuring safe and efficient driving under varying lighting conditions.

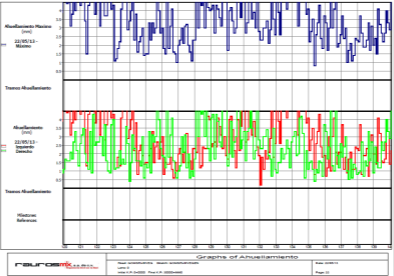

Rut Depth

Rut depth is a key parameter in evaluating pavement condition. This indicator provides valuable information on surface wear and deformation, directly impacting driving safety and comfort. Accurate rut depth measurement is carried out using specialized equipment such as Fiona I, Fiona V, and Profilometer.

Fiona I and Fiona V use advanced technologies such as laser scanning and high-resolution cameras to assess pavement texture and condition. These systems collect detailed data that contribute to precise rut depth determination. Profilometers measure road elevation along its length, allowing a comprehensive evaluation of surface deformations.

The combination of these equipment provides road authorities with a complete understanding of rutting depth and its impact on pavement quality.

Macrotexture

Pavement macrotexture is a critical element in evaluating road safety and ride comfort. It refers to large-scale surface irregularities that play a significant role in water drainage and skid resistance. To accurately measure macrotexture, specialized tools such as Fiona I, Fiona V, and Profilometer are used.

Fiona I and Fiona V employ laser scanning and high-resolution imaging technologies to assess pavement texture and surface characteristics. These systems collect detailed data essential for macrotexture determination. The Profilometer measures road elevation over distance, enabling a comprehensive evaluation of large-scale surface features.

Macrotexture data obtained using Fiona I, Fiona V, and the Profilometer is essential for informed maintenance and rehabilitation decisions, ensuring safe and comfortable travel for road users.